When it comes to reliable, durable, and cost-effective packaging solutions, Dazi Luoyang Plastic Industry Co., Ltd. stands out as a trusted name in the global market. Specializing in the production and supply of high-quality Jumbo Bags, also known as FIBCs (Flexible Intermediate Bulk Containers), we are committed to delivering products that meet the highest industry standards. Whether you’re in agriculture, chemicals, construction, or food processing, our Jumbo Bags are designed to streamline your operations and protect your goods during storage and transportation.

Superior Quality Jumbo Bags: Our Jumbo Bags are crafted from premium-grade polypropylene, ensuring exceptional strength, durability, and resistance to wear and tear. Whether you need standard designs or custom solutions, we’ve got you covered.

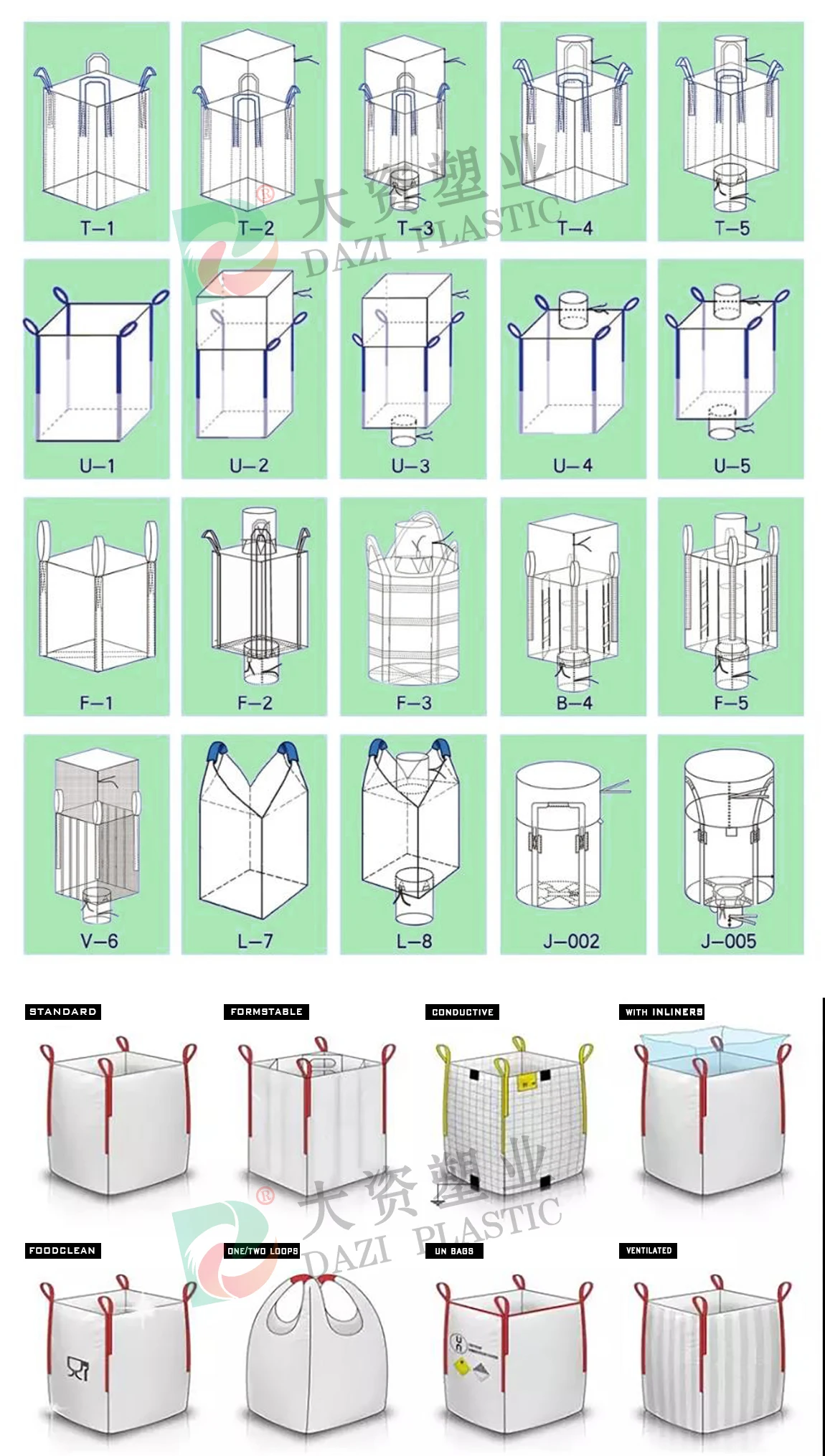

Wide Range of Options: From U-Panel, Circular, and Four-Panel Jumbo Bags to Conductive, Food-Grade, and Anti-Static FIBCs, we offer a diverse range of products tailored to meet your specific needs.

Customization at Its Best: At Dazi Luoyang Plastic Industry Co., Ltd., we understand that every business is unique. That’s why we provide fully customizable Jumbo Bags, including options for size, weight capacity, lifting loops, and printing. Let us create the perfect packaging solution for your brand.

Global Export Expertise: As a leading Jumbo Bag manufacturer and exporter, we have a proven track record of delivering top-notch products to clients worldwide. Our efficient logistics network ensures timely delivery, no matter where you are.

Eco-Friendly Solutions: Sustainability is at the core of our operations. Our Jumbo Bags are reusable, recyclable, and designed to minimize environmental impact, helping you achieve your green initiatives.

Our FIBC Bulk Bags are versatile and widely used across various industries:

Agriculture: For storing and transporting grains, seeds, and fertilizers.

Chemicals: Safe handling of powders, granules, and hazardous materials.

Construction: Ideal for cement, sand, and other construction materials.

Food Industry: Compliant with food-grade standards for safe storage of edible products.

Mining: Durable and reliable for heavy-duty applications.

Jumbo Bags

FIBC Bags

Bulk Bags

Flexible Intermediate Bulk Containers

Jumbo Bag manufacturer

Jumbo Bag exporter

Custom Jumbo Bags

U-Panel Jumbo Bags

Circular Jumbo Bags

Four-Panel Jumbo Bags

Conductive FIBCs

Food-Grade Jumbo Bags

Anti-Static FIBCs

Polypropylene Jumbo Bags

Eco-Friendly Bulk Bags

Dazi Luoyang Plastic Industry Co., Ltd.

At Dazi Luoyang Plastic Industry Co., Ltd., we pride ourselves on being more than just a supplier – we are your trusted partner in packaging solutions. Our commitment to quality, innovation, and customer satisfaction has made us a preferred choice for businesses worldwide. Whether you need standard Jumbo Bags or custom-designed FIBCs, we have the expertise and resources to meet your requirements.

Contact us today to learn more about our products and how we can help you optimize your packaging processes. Let’s work together to take your business to new heights with our premium Jumbo Bags!

|

Description

|

FIBC/Jumbo bag/bulk bag/ pp big bag/Flexible container bag professional manufacturer

|

|

Type of bag

|

Tubular/Circular/U-panel shape//Rectangular

|

|

Material

|

100% Virgin PP

|

|

Fabric

|

Laminated/Plain/Vent/Conductive

|

|

Size

|

Customized

|

|

GSM

|

110gsm-230gsm

|

|

Color

|

Customized

|

|

Printing

|

Customized

|

|

Top

|

Full open/Filling spout/Top skirt/Duffle

|

|

Bottom

|

Flat/plain/with discharge spout

|

|

Liner

|

Liner(HDPE, LDPE) or Customized

|

|

Lifting loop

|

Cross-corner loops/4 Point 2 Strap lifting loop/Double Stevedore Strap/with belt/Fully belt loop/Loop in loop

|

|

Sewing

|

Plain/chain/chain lock with optional soft-proof

|

|

Ropes

|

1 or 2 around the bag body/customized

|

|

SWL

|

500-2000KG

|

|

SF

|

5:1/6:1/or as customer's requirement

|

|

Treatment

|

UV treated or not UV treated

|

|

Surface Dealing

|

Coated or plain,printing or no printing

|

|

Usage

|

Storage and packing

Mine,ore,fertilizer,chemical,onion,potato,grain,wheat,maize,rice,peanut,sugar,salt,agriculture,building material,powder,cement,etc. |

|

Processing

|

Yarn drawing-Circular weaving/Webbing-Quality inspection-Coating-Film

blowing-Cutting-Printing-Sewing-Checkout-Packaging-Transportation |

|

Delivery time

|

15-30 days

|

|

Certification

|

ISO22000, ISO9001, ISO14001, LABORDATA, etc.

|

|

Remark

|

Please let us know your specific requirements

|