FIBC and IBC are two types of containers widely used in various fields, representing flexible medium bulk containers and medium bulk containers respectively. In order to conveniently and intuitively understand the similarities and differences between them, this article will introduce the meaning, design, advantages and disadvantages of FIBC and IBC respectively. FIBC is a flexible medium sized bulk container, which is generally designed to be square, of course, there are some examples, such as circular seals. At the same time, in order to facilitate the transportation of the crane, it is also equipped with some rings; FIBC is usually made from a woven outer layer of polypropylene, but can also be lined to meet the sanitary requirements of certain industries, such as the transportation of raw materials in the food processing industry, or the protection of raw materials against moisture.

FIBC takes up almost no space in the hollow case, and its light weight also reduces shipping costs; The low relative cost of FIBC compared to rigid IBC gives it a big advantage when packaging finished products. In addition, FIBC has connectable nozzle materials, which makes them efficient when loading and discharging materials, while reducing the risk of dust or product spills. However, handling some raw materials in FIBC, especially in the loading and unloading process, if the nature of the goods and FIBC is not considered, then it is easy to lead to risks such as dust explosion. IBC is a medium-sized bulk container, which is a mobile container with hard walls. It has two main designs, one is a suitcase, which is square, with a round feed port at the top and a rectangular discharge port at the bottom, and is shaped like a door. This suitcase form can be easily stacked and unloaded, but in terms of health, its discharge door is not very convenient, so it needs another design method - conical IBC, its upper part is square, the bottom is designed as a cone, and the bottom can be installed with various valves, such as simple manual butterfly valves. Although FIBC and IBC have their own different use environments and advantages and disadvantages, but FIBC and IBC are designed to meet the needs of large-scale material transportation and storage, in order to meet the needs of actual production.

|

Description

|

FIBC/Jumbo bag/bulk bag/ pp big bag/Flexible container bag professional manufacturer

|

|

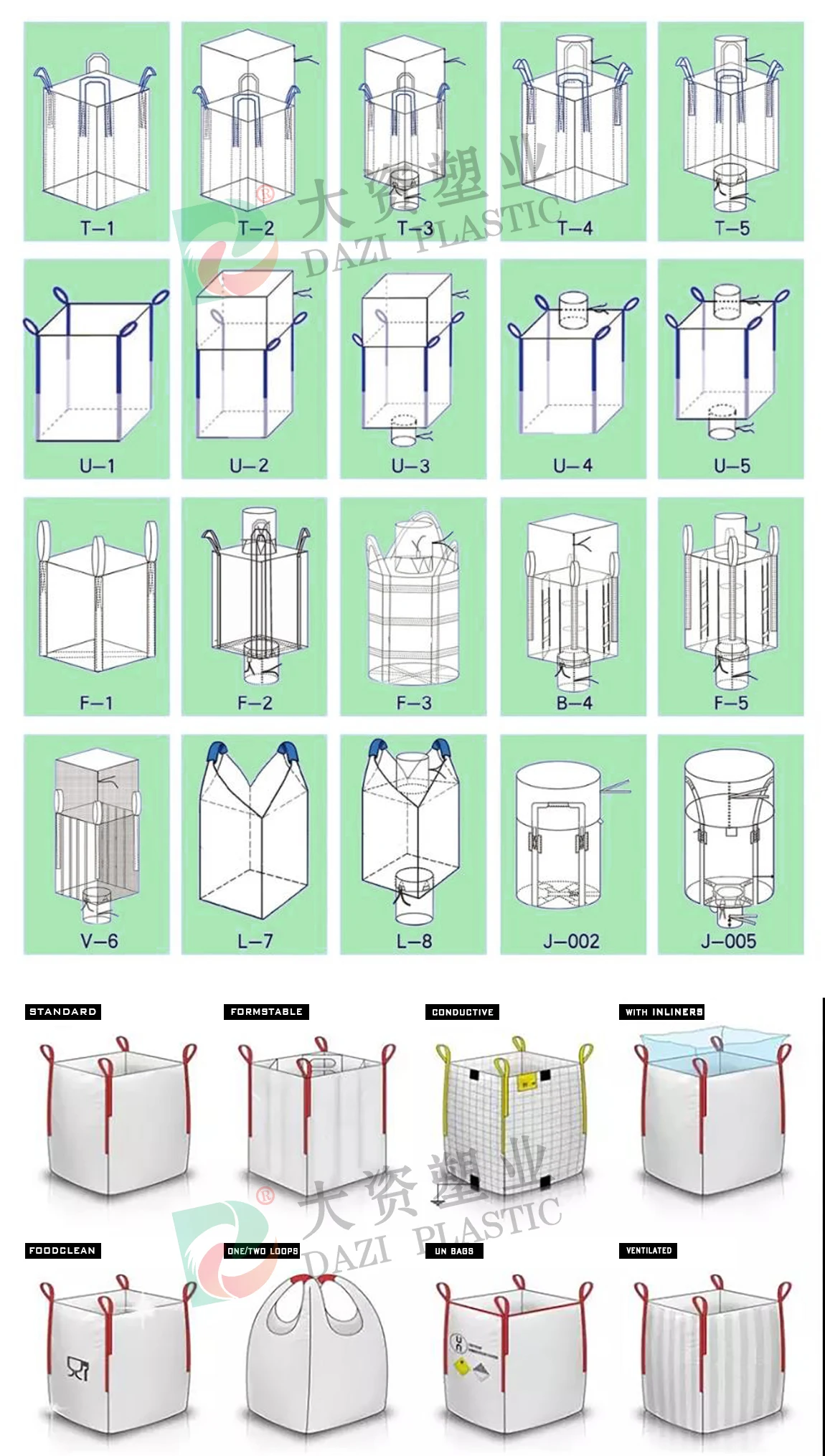

Type of bag

|

Tubular/Circular/U-panel shape//Rectangular

|

|

Material

|

100% Virgin PP

|

|

Fabric

|

Laminated/Plain/Vent/Conductive

|

|

Size

|

Customized

|

|

GSM

|

110gsm-230gsm

|

|

Color

|

Customized

|

|

Printing

|

Customized

|

|

Top

|

Full open/Filling spout/Top skirt/Duffle

|

|

Bottom

|

Flat/plain/with discharge spout

|

|

Liner

|

Liner(HDPE, LDPE) or Customized

|

|

Lifting loop

|

Cross-corner loops/4 Point 2 Strap lifting loop/Double Stevedore Strap/with belt/Fully belt loop/Loop in loop

|

|

Sewing

|

Plain/chain/chain lock with optional soft-proof

|

|

Ropes

|

1 or 2 around the bag body/customized

|

|

SWL

|

500-2000KG

|

|

SF

|

5:1/6:1/or as customer's requirement

|

|

Treatment

|

UV treated or not UV treated

|

|

Surface Dealing

|

Coated or plain,printing or no printing

|

|

Usage

|

Storage and packing

Mine,ore,fertilizer,chemical,onion,potato,grain,wheat,maize,rice,peanut,sugar,salt,agriculture,building material,powder,cement,etc. |

|

Processing

|

Yarn drawing-Circular weaving/Webbing-Quality inspection-Coating-Film

blowing-Cutting-Printing-Sewing-Checkout-Packaging-Transportation |

|

Delivery time

|

15-30 days

|

|

Certification

|

ISO22000, ISO9001, ISO14001, LABORDATA, etc.

|

|

Remark

|

Please let us know your specific requirements

|