In today’s fast-paced logistics and industrial sectors, efficient, durable, and eco-friendly packaging is no longer a luxury—it’s a necessity. FIBC Bulk Bags (Flexible Intermediate Bulk Containers), also known as 吨袋 (Ton Bags) or 集装袋 (Jizhuang Bags), have emerged as the go-to solution for businesses seeking to optimize storage, transportation, and sustainability. Let’s explore why these versatile containers are revolutionizing industries worldwide.

1. Unmatched Durability & Safety

FIBC Bulk Bags are engineered with high-strength polypropylene (PP) or polyethylene (PE) materials, ensuring exceptional resistance to tearing, punctures, and corrosion. With a 5:1 safety factor (5 times the rated load capacity), they safely handle heavy-duty applications, from 500kg to 2,000kg loads, even in harsh environments like chemical or agricultural settings .

Key Features:

- UV-resistant coatings for prolonged outdoor use.

- Anti-slip base designs to stabilize stacked loads.

- Reinforced stitching and welding for seam integrity .

2. Cost-Effective & Space-Saving Design

Unlike rigid containers, FIBC Bags are lightweight (3.5–4.5kg per bag) and collapsible, reducing shipping and storage costs by up to 80%. Their foldable nature allows seamless integration with forklifts and cranes, streamlining loading/unloading processes .

Cost Savings:

- Eliminates the need for pallets or secondary packaging.

- Reduces transportation frequency through optimized cube utilization .

3. Eco-Friendly & Reusable

As global industries pivot toward sustainability, FIBC Bags shine with 100% recyclability and reusability. A single bag can withstand multiple cycles, significantly cutting down plastic waste and carbon footprints—aligning with circular economy goals .

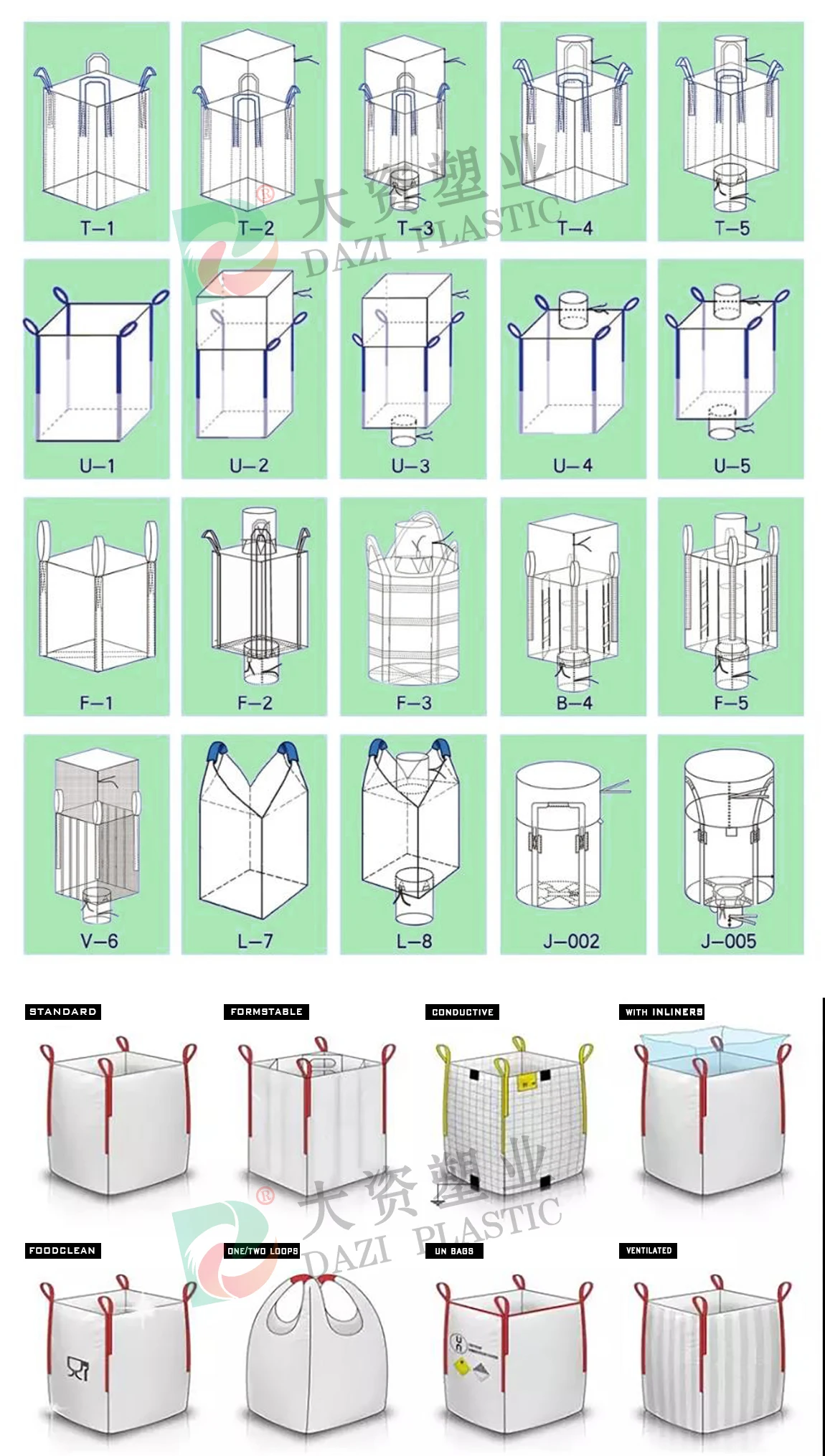

4. Customization for Diverse Applications

FIBC Bags are tailored to meet industry-specific needs:

- Food & Agriculture: FDA-approved liners for grains, seeds, and fertilizers.

- Chemicals: Anti-static designs for hazardous powders.

- Construction: Waterproof coatings for cement and sand.

- Mining: Heavy-duty options for ores and minerals .

Custom Options:

- Adjustable spouts (top/fill and bottom/discharge).

- Lifting loops (4-loop or 2-loop designs).

- Anti-UV or flame-retardant treatments .

5. Compliance & Quality Assurance

Reputable manufacturers adhere to ISO 9001 and international standards (e.g., EU, US, Australian certifications), ensuring product safety and performance. Rigorous testing—including load capacity, drop tests, and UV exposure—guarantees reliability .

6. Future-Ready Innovations

The FIBC industry is evolving with:

- Smart Bags: IoT-enabled sensors for real-time tracking.

- Biodegradable Materials: Reducing environmental impact.

- Ergonomic Designs: Enhanced grip and stacking stability .

Why Choose Us?

At [Your Company Name], we combine 20+ years of expertise with cutting-edge technology to deliver FIBC Bags that exceed expectations. Our custom solutions, competitive pricing, and 24/7 support ensure your logistics chain runs smoothly.

SEO-Optimized Keywords:

- FIBC Bulk Bags Supplier

- Custom Ton Bags

- Eco-Friendly Jizhuang Bags

- Durable PP Woven Sacks

Call to Action:

Ready to upgrade your packaging? Contact us today for a free consultation and discover how FIBC Bulk Bags can transform your operations. Visit [www.dazifibc.com ] or email sales@dazisuye.com to request a quote!

Meta Description:

Discover high-quality FIBC Bulk Bags for agriculture, chemicals, and construction. Custom designs, eco-friendly solutions, and global certifications. Boost efficiency and sustainability—request a quote now!

Alt Text for Images:

- "Heavy-Duty FIBC Bags for Industrial Transport"

- "Customizable Bulk Bags with UV Protection"

Luoyang City Dazi plastic Co., Ltd. is a comprehensive integrated enterprise with the production of yarn drawing, circular weaving, webbing, coating, film blowing, sewing and accessories material (sewing thread, polyester filler cord, etc.). Our company has a staff of over 458 people, covers an area of about 59,000 square meters, including a building area of about 49,000 square meters, and owns 4 modern plants which include the project of one hundred thousand level dust-free workshop for flexible container bags, the finished product out put of this project is about 80000 pcs / month. This project is equipped with complete physical and chemical indicators testing equipment, and all the equipment of this project adopt the advanced equipment at home and abroad, featuring advanced performance, convenient operation, stable operation, safety and reliability. Together with excellent polypropylene raw materials, stable auxiliary materials and advanced production technology, we can provide various products to customers and friends. Besides, We possess National industrial product production license and Informatization integration management system assessment certificate, and have passed I S O 9 0 0 1, I S O 1 4 0 0 1, O H S A S 1 8 0 0 1, and I S O 2 2 0 0 0. The advanced production equipment,professional production technology, scientific management system and complete detection means has guaranteed our products reach the international standard and sell well in over 10 countries and regions, especially in southeast Asia, Europe, United states.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

|

Description

|

FIBC/Jumbo bag/bulk bag/ pp big bag/Flexible container bag professional manufacturer

|

|

Type of bag

|

Tubular/Circular/U-panel shape//Rectangular

|

|

Material

|

100% Virgin PP

|

|

Fabric

|

Laminated/Plain/Vent/Conductive

|

|

Size

|

Customized

|

|

GSM

|

110gsm-230gsm

|

|

Color

|

Customized

|

|

Printing

|

Customized

|

|

Top

|

Full open/Filling spout/Top skirt/Duffle

|

|

Bottom

|

Flat/plain/with discharge spout

|

|

Liner

|

Liner(HDPE, LDPE) or Customized

|

|

Lifting loop

|

Cross-corner loops/4 Point 2 Strap lifting loop/Double Stevedore Strap/with belt/Fully belt loop/Loop in loop

|

|

Sewing

|

Plain/chain/chain lock with optional soft-proof

|

|

Ropes

|

1 or 2 around the bag body/customized

|

|

SWL

|

500-2000KG

|

|

SF

|

5:1/6:1/or as customer's requirement

|

|

Treatment

|

UV treated or not UV treated

|

|

Surface Dealing

|

Coated or plain,printing or no printing

|

|

Usage

|

Storage and packing

Mine,ore,fertilizer,chemical,onion,potato,grain,wheat,maize,rice,peanut,sugar,salt,agriculture,building

material,powder,cement,etc.

|

|

Processing

|

Yarn drawing-Circular weaving/Webbing-Quality inspection-Coating-Film

blowing-Cutting-Printing-Sewing-Checkout-Packaging-Transportation

|

|

Delivery time

|

15-30 days

|

|

Certification

|

ISO22000, ISO9001, ISO14001, LABORDATA, etc.

|

|

Remark

|

Please let us know your specific requirements

|

|

|

|

We can design and produce various kinds of products according to customer's requirements.

Production process: Yarn drawing--Circular weaving/Webbing--Quality inspection--Coating-Film blowing--Cutting--Printing--Sewing--Checkout-Packaging--Transportation

Q1:What's your Product Range?

1. Jumbo bag/ ton bag/ pp big bag/ super sack/ pp container bag.

2. Plastic woven bag,poly-woven bag.

3. Semi-finished product of all above(pp material, pp fabric, pp webbing, pp liner, Sewing thread, Leakproof sliver)

Q2:Are you a manufacture?

Yes,We have been in providing professional solution in plastic woven industry for over 20 years.

Q3:Do you have stock products to sell?

No ,We work on OEM orders.That means size material quantity packaging solution,etc will depend on your requests.

Q4:What information should I let you know if I want to get a quotation?

-The size of the bag (Length * Width * Height) or (diameter * height).

-The material and surface handing.

-The bag's color and the loop's color.

-The SWL and SF.

-The order quantity.

-The bag's working condition, usage, temperature, light application time, the goods save way.

- If it is possible, please also provide with picture design sketch for checking, sample will be best for clarifying, If not we

will recommend relevant products with details for your reference.

Q5: How can we guarantee quantity?

-Always a pre-production sample before mass production;

-Always final inspection before shipment;

Q6:How many time will the sample be finished? How your factory production scale?

-Generally,1-2 days for sample making.

-The lead time of mass production will depend on quantity,quality,existing orders.

Q7:How do you inspect the quality of our order?

-We have first-rate production equipment, advanced production technology, scientific management system and complete detection

means and also expert QC to ensure the quality of products.