In the context of globalized trade and bulk cargo transportation, how can we achieve safe, efficient, and cost-effective loading, unloading, and storage and transportation? FIBC, with its unique structural design and material advantages, has become a "transportation weapon" for industries such as chemicals, minerals, and grains. Compared to traditional packaging, the bulk bag, with its lightweight, foldable, and high-load-bearing characteristics, redefines the transportation standards for bulk materials.

1. Superb Load-bearing Capacity, One Bag Equal to Multiple Boxes

FIBC is made of high-strength polypropylene (PP) or polyethylene (PE) woven fabric, combined with anti-tear base fabric and reinforced sewing techniques. A single bag can bear a weight of 0.5-2.5 tons, far exceeding that of ordinary woven bags or cardboard boxes. Its three-dimensional structure design evenly disperses pressure and avoids local damage, making it particularly suitable for heavy bulk materials such as ores, fertilizers, and starch.

2. High Space Utilization Rate, More Cost-effective Storage and Transportation

Compact storage: The empty bag can be compressed to 1/10 of its original volume, saving 90% of storage space;

Stable stacking: Square or circular design ensures that multi-layer stacking does not tip over, reducing the risk of shaking during transportation;

Convenient loading and unloading: Standardized straps or forklift holes, mechanized operation efficiency increases by more than 50%, significantly reducing labor costs.

3. Moisture-proof and Dust-proof, Comprehensive Protection for Goods

According to requirements, FIBC can be customized with various functional inner linings:

Moisture-proof inner film (PE coating): Protecting fertilizers, feed, etc., which are susceptible to moisture;

Anti-static design: Suitable for chemical powders, avoiding friction fires;

Breathable net fabric: Used for agricultural product storage, preventing mold.

4. Environmentally Friendly and Recyclable, a Sustainable Development Choice

High-quality FIBC can be reused 5-10 times, and after damage, they can be recycled into granules, reducing disposable packaging waste. Compared to wooden crates or iron buckets, their production energy consumption is lower, and carbon emissions are reduced by more than 30%, conforming to the trend of green logistics.

5. Flexible Customization, Suitable for Multiple Scenarios

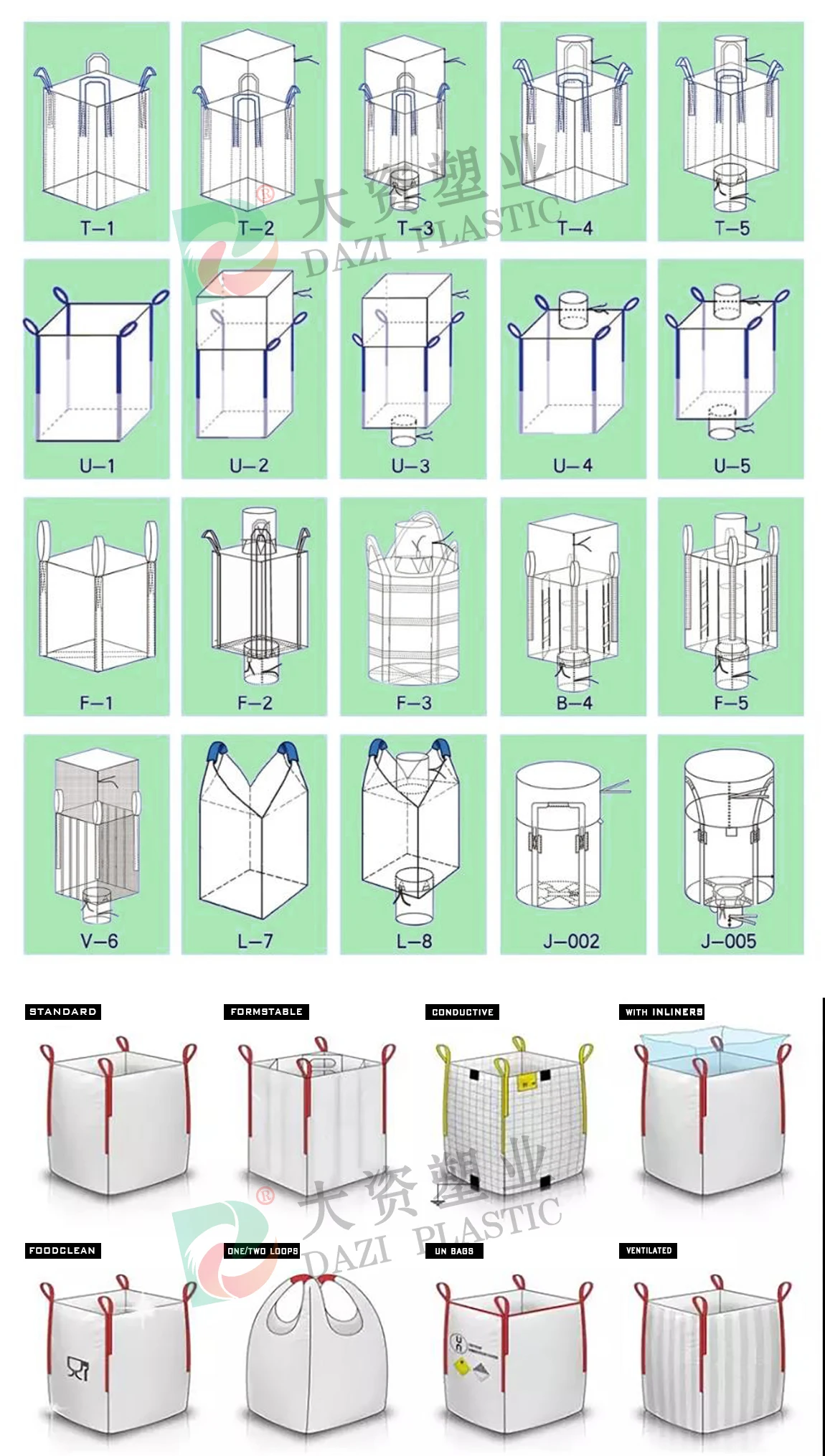

From standard models to special requirements, the bulk bag supports all-round customization:

Size: 500kg mini-ton bags to 2.5-ton large bags;

Structure: Open type, discharge valve type, leak-proof bottom seal, etc.;

Printing: Enterprise LOGO, transportation labels, safety warnings, etc., enhancing brand image.

Whether it is to reduce logistics costs, improve loading efficiency, or meet environmental protection compliance requirements, FIBC, with its practicality and economy, has become an indispensable partner in modern supply chains. Choosing the appropriate bulk bag is choosing a smarter and more sustainable logistics solution!

|

Description

|

FIBC/Jumbo bag/bulk bag/ pp big bag/Flexible container bag professional manufacturer

|

|

Type of bag

|

Tubular/Circular/U-panel shape//Rectangular

|

|

Material

|

100% Virgin PP

|

|

Fabric

|

Laminated/Plain/Vent/Conductive

|

|

Size

|

Customized

|

|

GSM

|

110gsm-230gsm

|

|

Color

|

Customized

|

|

Printing

|

Customized

|

|

Top

|

Full open/Filling spout/Top skirt/Duffle

|

|

Bottom

|

Flat/plain/with discharge spout

|

|

Liner

|

Liner(HDPE, LDPE) or Customized

|

|

Lifting loop

|

Cross-corner loops/4 Point 2 Strap lifting loop/Double Stevedore Strap/with belt/Fully belt loop/Loop in loop

|

|

Sewing

|

Plain/chain/chain lock with optional soft-proof

|

|

Ropes

|

1 or 2 around the bag body/customized

|

|

SWL

|

500-2000KG

|

|

SF

|

5:1/6:1/or as customer's requirement

|

|

Treatment

|

UV treated or not UV treated

|

|

Surface Dealing

|

Coated or plain,printing or no printing

|

|

Usage

|

Storage and packing

Mine,ore,fertilizer,chemical,onion,potato,grain,wheat,maize,rice,peanut,sugar,salt,agriculture,building material,powder,cement,etc. |

|

Processing

|

Yarn drawing-Circular weaving/Webbing-Quality inspection-Coating-Film

blowing-Cutting-Printing-Sewing-Checkout-Packaging-Transportation |

|

Delivery time

|

15-30 days

|

|

Certification

|

ISO22000, ISO9001, ISO14001, LABORDATA, etc.

|

|

Remark

|

Please let us know your specific requirements

|